The pilot demonstrated the benefits of a digital platform in the reuse of building components

Bringing the circular economy into practice requires innovative tools and effective collaboration. Finnish company Spolia Design and Danish firm Zupply tested a digital platform for mapping reusable building materials during the renovation of the over 120-year-old Lindström House.

This text was translated with the help of AI.

The reuse of building materials is a key step towards more sustainable construction. A digital platform is a valuable tool in this process, as it enables efficient mapping of building components and materials, as well as real-time information sharing among project stakeholders. This also supports the development of circular economy innovations.

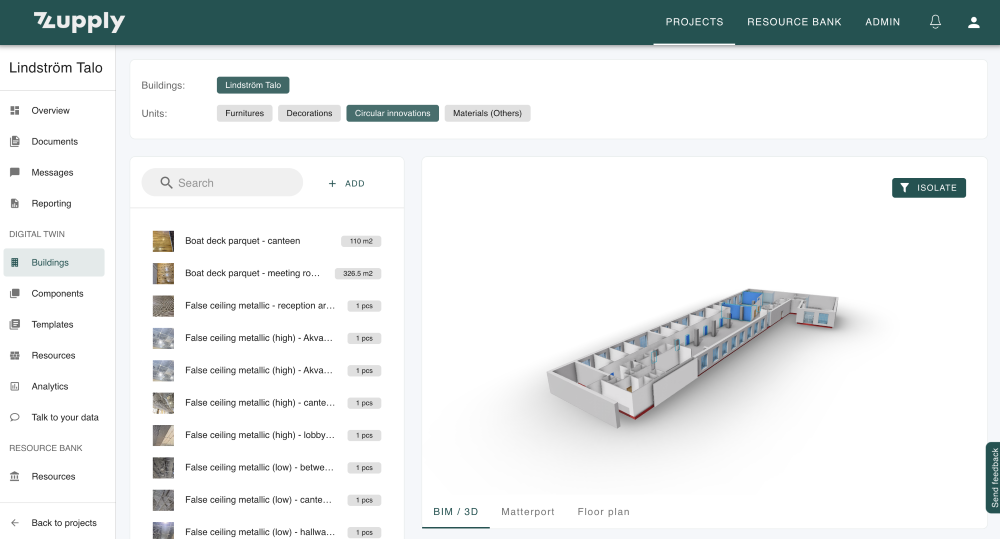

Danish circular economy software company Zupply and Finnish company Spolia Design, specializing in consulting on the reuse of building components, combined their digital approach with practical circular economy solutions. The pilot was conducted as part of the Helsinki Circular Economy Cluster Program’s innovation challenge. It took place at Lindström House in Helsinki, which is owned by Castellum. During the pilot, Lindström House was undergoing renovation. The pilot utilized Zupply’s digital platform and Spolia Design’s expertise in circular economy practices

A pilot project in Finnish construction

Zupply’s platform is already widely used in construction projects across Denmark and other EU countries, but this was the first time it was tested in Finland.

“We wanted to test in a real project how a digital platform can enhance the hands-on implementation of the circular economy and facilitate information sharing among different parties. Renovation and demolition sites contain a significant amount of valuable materials. The earlier we can make a site’s building products and furnishings visually available to a broad audience, the better this information can be utilized in planning,” says Petri Salmi, co-founder of Spolia Design.

The digital platform ensures that up-to-date information is accessible to all parties, increasing process efficiency and transparency. It also serves as a platform where images and real-time product information can be stored and updated throughout the project.

“Our platform generates calculations and data on carbon footprints and the suitability of different materials for circular economy applications. We believe that digitalization and efficient information sharing can significantly improve the reuse rate of materials in the construction industry,” says Zupply’s CEO, Jose ‘Pepe’ Tavares.

Digital twins at the core

During the Lindström House renovation, Zupply’s digital platform enabled the efficient mapping of building components and materials, utilizing automation. A digital twin of the space was created using 3D imaging and modeling, allowing for visual inspections and optimizing the reuse of materials. This also helped the space planning. After the renovation, the digital twin was updated to store up-to-date material information of the site.

“AI and automation make the process scalable. This is an advantage when looking to implement circular economy practices across multiple projects,” says Pepe Tavares.

In addition to the digital twin, a circular economy strategy was developed, and a material survey was conducted, which remained available as a product information database. Digital product cards documented the quantities of building components, material details, and Spolia Design’s guidelines for dismantling and refurbishing building parts.

“Contractors used the product cards and responded positively to them. Renovation work has fewer surprises when someone has already examined the structures,” says Petri Salmi.

A manual for the entire construction industry

What did the pilot uncover? At the very least, it demonstrated that combining digital and real-world work can be successful.

The experiment also highlighted the importance of planning the schedule, roles, and division of work in circular economy projects in advance. Time must be allocated for tasks such as refurbishing demolition materials, designing new applications, and developing prototypes.

The renovation and circular economy project for Lindström House were carried out in parallel, which posed certain challenges in aligning schedules and goals.

Zupply and Spolia Design compiled the lessons learned into a manual that provides practical guidelines for implementing circular economy principles in building renovation projects. The manual is intended for use by the entire construction industry.

“In circular economy projects, having the courage to experiment and adopt new solutions is crucial. Property owners and developers need to be open to new proposals and willing to invest in new practices. I believe that property owners will gradually begin to recognize the value of reusable materials,” says Petri Salmi.